We like it clean

Our small but mighty valves play a crucial role in the function of medical devices, pharmaceutical and food packaging, and many other technology-driven industries world wide. The health and well-being of millions of consumers worldwide depend on them. That’s why we take every precaution to ensure our valves are made and delivered in the most pristine condition technology permits.

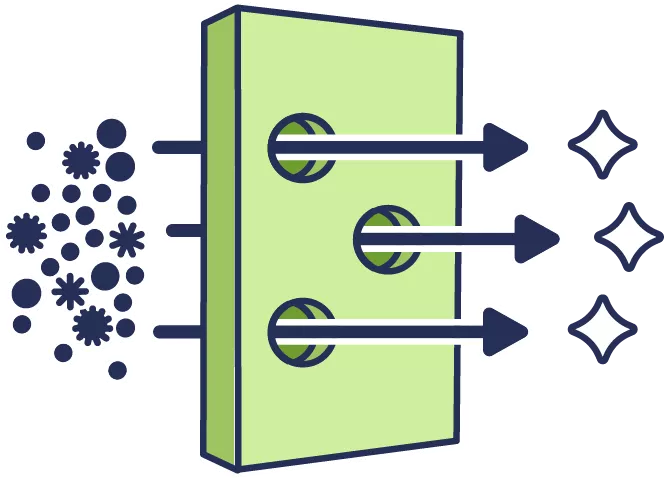

Cleanliness

All of our valves are made in our ISO class 8 clean room environment assuring the supply of clean components ready for use in medical devices and any other industry. Best equipment and stringent Work Instructions assure that our cleanliness is always up-to-date. Customers may expect zero defect parts that meet our exacting standards. Upon final inspection, the valves are bulk packaged, double bagged in cleanroom bags, ready for integrating seamlessly into your manufacturing workflow.

Clean and safe products aren’t just about preventing airborne particles and maintaining strict hygiene standards; they reflect our core values, commitment to our process, and our promise to you. They stand as active reminders that details matter, especially when it comes to manufacturing clean and safe miniature valves. Customers who choose Minivalve aren’t just getting valves; they’re getting our unrivaled attention to detail in every part.