Umbrella valves

Umbrella Valves have been around for years. Their applications include vessel/vehicle vent valves (e.g.: vehicle fuel tanks), intake and outlet valves (e.g.: piston and diaphragm pumps), one-way check valves (e.g.: disposable breathing masks), and countless other fluid and vapor control functions found in medical devices, home appliances, vehicles, toys, etc.

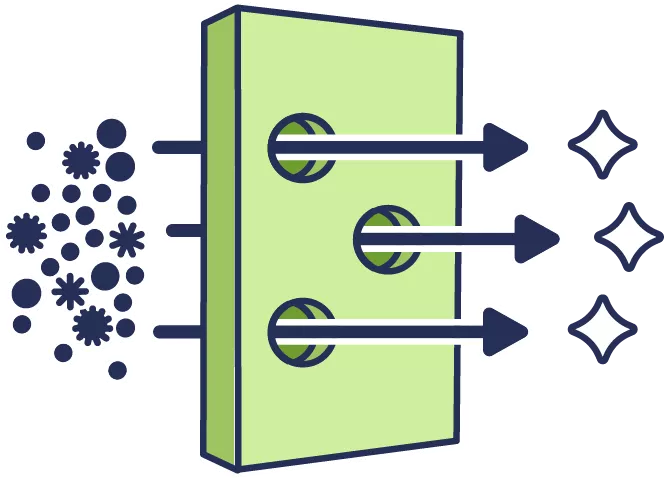

Umbrella Valves are elastomeric valves that feature circular diaphragms shaped, like mini-umbrellas (hence their name), that act as sealing disks. These elastomeric components are vital and integral pieces in backflow prevention devices (also known as one-way or check valves) commonly used in venting systems (e.g.: pressure relief environments) and in metering valves. When mounted in a ‘seat’, the convex diaphragms flatten over the entire valve seat enabling it to absorb pressure irregularities while successfully creating a barrier against any counter pressure.

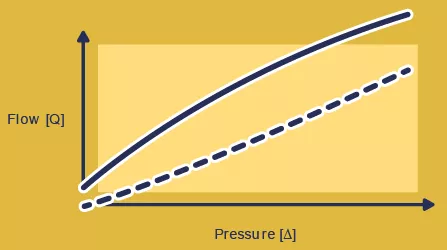

Its simple elegance works like this. Once sufficient pressure in the head volume is created, the built-up force lifts the convex diaphragm from the seat and the Umbrella Valve allows forward flow, in a one-way stream. The design of the valve and seat allows for a predetermined flow rate and pressure. Any change in flow direction triggers the Umbrella Valve to snap back into the seat, stopping backflow in the opposite direction. Minivalve engineers specialize in determining our Umbrella Valve opening thresholds. All our standard Umbrella Valves are easily modified to suit exact specifications and requirements. (Please enquire about our capabilities.) In contrast to other valve types (like spring-loaded disc valves for example), the two main advantages of Umbrella Valves are: 1) their flexible, elastic material and; 2) their pre-loaded convex shape. Together, these create the sealing force and barrier against the seat. These valves also feature a central stem or axle (also like an umbrella) which holds the operating component firmly in place, completely removing the need for any additional components like springs or central (circumferential) disc positioners. All of which greatly simplify both design and assembly, and makes the valve hyper-adaptable to even the smallest spaces. Its low number of parts and relative ease of assembly also make it highly cost-effective.

Features & Benefits Recap

- Immediate, positive seal

- Position independent (it can be placed virtually anywhere)

- Variable pressure-opening, configured in conjunction with seat thickness

- High flow rate to passage/tube size ratio

- Corrosion resistant

- Wear-resistant

- Highly cost-effective

Integration

Minivalve Umbrella Valves work with specific seat designs that enable them to be adapted and integrated seamlessly into the plastic or metal housing of any application. In order to determine the exact seat design, we advise you to consult Minivalve’s recommended seat design instructions first. Then, adapt these further according to your own specifications so that they’ll match the exact needs of your product. Here’s why. Say your valve requires a high flow rate. In such cases, we suggest making the flow orifices in the seat as large as possible, which can be done by creating banana or C-shaped slots as openings. On the other hand, if your valve requires a low flow rate, and/or needs to withstand high reverse/back pressure, we suggest only creating one or two small flow orifices. Then ensure: A) that the valve seat has sufficient surface area to support the whole diaphragm under any back pressure and; B) that the outer diameter of the flow’s surface area doesn’t sit too closely to the edge of the umbrella (which could create leakage). Our engineers would be happy to help guide you through this process.

Minivalve Umbrella Valves are available in a variety of elastomeric materials including: medical and food grade silicone and hydrocarbon resistant fluorosilicone rubber, specifically engineered to handle a broad range of substances and temperatures.

Umbrella Valve Types

We manufacture 3 main types of Umbrella Valves for installation/integration.

- Pull-in models with long tails

- Push-in models with short tails

- Belleville Valves with tails on the opposite side

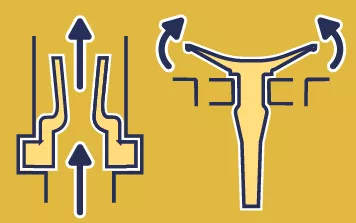

Pull-In

By far the most common type, Pull-In Umbrella Valves are well suited for hand assembly. For installation, you simply thread the long tail directly through a central bore (hole) situated in the seat, then the tail is ‘pulled-in’ (hence their name). Since this component will have been precision fitted, it pops snuggly into place and is ready for use. If the tail is too long after assembly, it can simply be snipped off.

Push-In

These types are generally preferred when the threading of a long tail in the central bore or hole is difficult. Or, when assembly is automated. Examples may include: the bottom of a deep cylinder; the upstream side of a given valve; or, in the inside wall of an inaccessible tank. Push-in types can be used in automated and semi-automated assembly line production. For automated assembly, there’s a notch in the top of the valve which you can stick a pin into.

Belleville

The shape of this valve’s membrane resembles that of a Belleville spring washer (hence their name) and is held in place by an elastomeric hinge in the center. It behaves the same way too! Typically, once a predetermined amount of pressure builds up, the valve will suddenly ‘pop’ open. Whereas an Umbrella Valve’s stem can be slightly more restrictive for certain applications, the Belleville’s central stem is located further downstream from the valve portion and held in place by a retainer. This retainer can be an entirely separate component or, it can be an integral piece of the device into which it’s been incorporated. An example would be something like a cap or lid just above an Umbrella Valve.