Minivalve balls

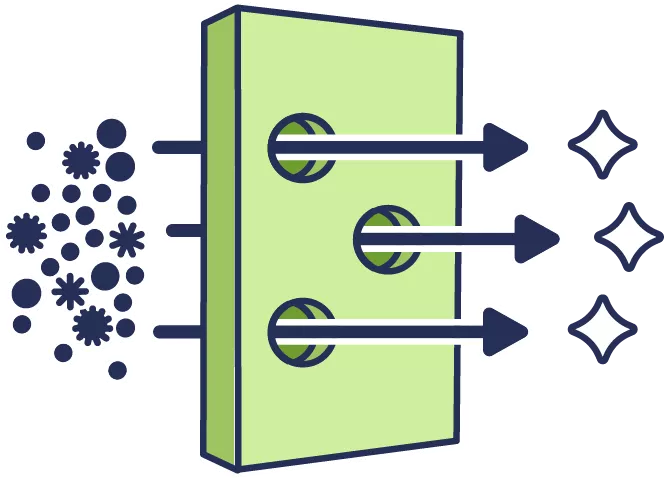

Minivalve balls are simple and effective check-valves (also known as one-way valves). Inside each, a proportionately sized ball literally floats freely around a flow orifice. Exposed to any sudden backflow pressure, the ball naturally slides back with the flow direction, sealing off the orifice and effectively creating a plug.

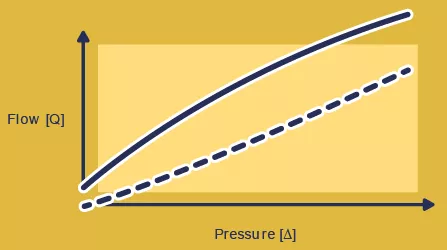

This particular type of free shutting valve only requires the smallest degree of pressure to open, while also requiring only some small degree of initial back flow pressure to close. Functionality can be adapted and further precision improvements made by using a spring to keep the valve against the seat. This can help prevent any backflow leakage. It can also be used to create another version of a pressure relief valve.

Our Minivalve balls are precision ground to make them perfectly round, smooth and completely free of any parting or molding lines. The rubber they’re made out of is strong enough to withstand medium to high pressures, while their surfaces are also soft enough to provide all the sealing power you will ever need. Especially in contrast to stiff plastic or steel balls. In all these ways, Minivalve balls offer the perfect valve component.

Minivalve balls Features & Benefits Recap::

- Unrivalled spherical shape

- No mold parting line, superior sealing quality

- Easy to assemble

- Highly cost-effective

Minivalve balls are available in Silicone and FKM materials.