Custom valve solutions

We’re always making new valves, whether for our catalog or a customer specific project. Our streamlined process, combined with our best equipped flow test lab and our in-house tool shop, enables us to provide rapid turnaround times and excellent part quality.

FIVE STEPS take your project from concept to serial production.

1Inquiry

First, we aim to get a better understanding of your project and what type of valve you are looking for. We consider how it integrates with your device, its role, and the functional purpose it serves. Then, we’ll discuss the most effective ways forward. It may be best to try one or two of our standard parts first, or perhaps not. Together, we decide on the fastest and most economical way forward.

“We might suggest trying some of our standard, off-the-shelf valves first. They’re in stock and ready supply. This might be the simplest and most expedient solution. It’ll also be the most economical.”

2Proposal

With a solid understanding of your project and needs, we compile a commercial proposal for your evaluation.

3Prototype tooling

Once you’ve given us the go-ahead, we come to action. The mold is further detailed and scheduled for manufacturing in our toolshop and the molding process is established. We keep a close eye on the schedule, ensuring the prototypes come to you in a timely fashion.

“We don’t run our tool shop to feed our bottom line. Rather, it’s designed to minimize your initial project investment and lower financial exposure from the outset.”

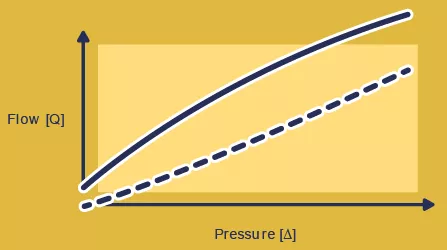

4Testing and validation

Once the first samples are done, we test them to confirm they perform as expected. Then, we send them to you for your own device testing and evaluation. Subsequently, we review our findings together. If tweaks need to be made, no problem (and all part of the process). If not, then great, we leave it with you to continue building it further into your design.

“Between our cutting-edge flow lab and our precision tool shop (all in-house), our engineering team and clients enjoy the perfect playground for creating high-performance valves with ease and speed.“

5Serial production

At each stage, form proto to production tooling, our process includes the application of stringent instruments and procedures to assure the expected output. What may start as “quick-and-dirty” samples will eventually pass through a tightly orchestrated quality assured development and tool build and serial production validation process. When it comes to new production parts we believe in prevention rather than correction. Finally, when your device is ready for the market, we ensure we have all tools, documentation, training and everything else in place to supply the volumes you need, whenever you need them, consistently, year after year.

Ready to get started?

Leave your contact details below and we’ll be in touch shortly.

"*" indicates required fields